Welcome to our website

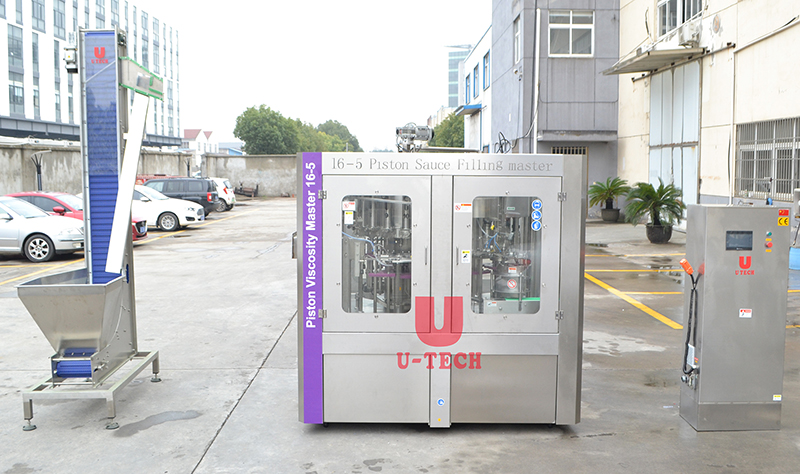

This UT series is an extremely flexible filler capable of filling accurately and rapidly any viscous liquids. Product delivery from your bulk tank to the pistons can be configured with a buffer tank utilizing a level-sensing float, a manifold with direct draw, or re-circulation methods. The Automatic Linear Piston Filler is manufactured with a 304 stainless steel frame and is capable of supporting 1 to 16 fill heads. PLC controls, touch screen HMI, food grade contact parts, stainless steel and anodized aluminum construction and many more features come standard. Automatic Piston Fillers are designed to add efficiency to any production line used in the cosmetic, food service, specialty chemical, pharmaceutical, and personal care industries. Additional options are available for sanitary, hazardous, flammable and corrosive environments.

Introduction

This UT series is an extremely flexible filler capable of filling accurately and rapidly any viscous liquids. Product delivery from your bulk tank to the pistons can be configured with a buffer tank utilizing a level-sensing float, a manifold with direct draw, or re-circulation methods. The Automatic Linear Piston Filler is manufactured with a 304 stainless steel frame and is capable of supporting 1 to 16 fill heads. PLC controls, touch screen HMI, food grade contact parts, stainless steel and anodized aluminum construction and many more features come standard. Automatic Piston Fillers are designed to add efficiency to any production line used in the cosmetic, food service, specialty chemical, pharmaceutical, and personal care industries. Additional options are available for sanitary, hazardous, flammable and corrosive environments.

Machine details

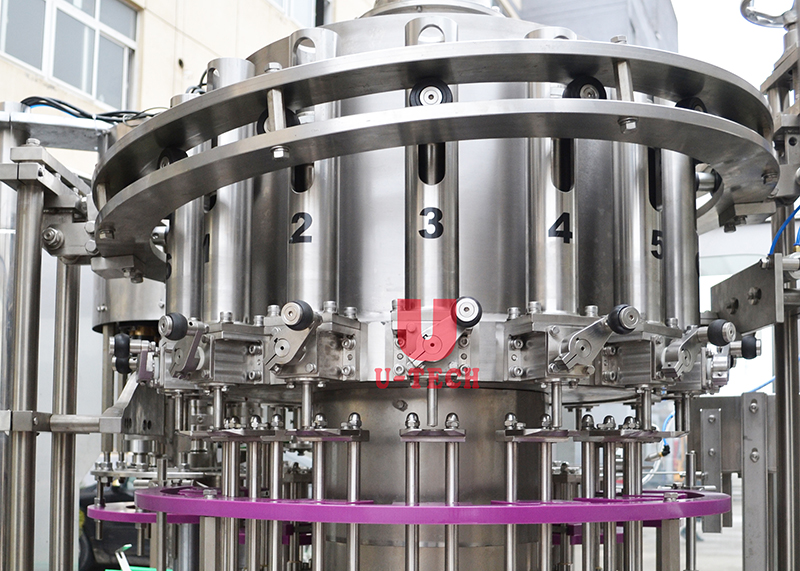

Micro-computer Filling Machine is suitable . It uses vertical structure with constant liquid level and time which realize the precise filling. It is controlled by the PLC, human interface and easy operation. The machine is equipped with electric scale weight feedback system which makes the volume adjust easier.

Technical parameter