Welcome to our website

Water treatment system,also called water filtration sterlizer system, is the process of purifying the raw water by a series equipments and devices to be drinkable.The water treatment equipment includes silica sand filter, active carbon filter, sodium-ion exchanger, precision filter, reverse osmosis, hollow fiber filter, ozone generator, ozone mixing tower and water tank, etc.

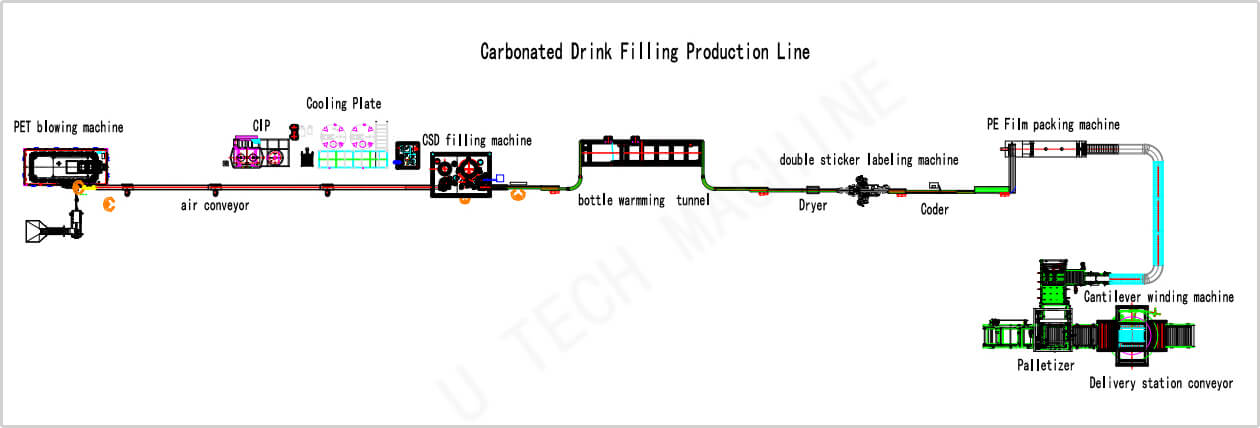

This project is to design for the carbonated drinks preparation to meet the client’s technics, which includes hot water section, sugar melting section, syrup storage section, sterilizing section, carbon mixing section. This design is popular in the modern beverage field worldwide, with the advantages of high efficiency, energy saving, continuous working, etc.

The machine is made with the newest technology introduced from Japan.It is in the leading position comparing with similar products in China.The mixer is mainly suitable for mixing process of all kinds of carbonated drinks.It is also used in mixing of slurry drink,fermented drink and other drinks.

QHS series mixer is designed and made for improving the proportion of water ,syrup and carbon dioxide.It adopts foreign advanced technology-static mixer to lighten water layer,increase carbonizing time,assure mixing result and deoying.

CIP is specially designed for the clean-up of beverage production line and filling equipment, with three cleaning sections of acid, alkali and heated water.

The pet stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine. It has various cavities and the maximum capacity of the products is 20L. It can blow bottles in shapes: Carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers etc. Which is made of plastic of crystalline type, such as PET and PP etc.

DCGF series carbonated drinks filling line is used to produce PET bottled carbonated drinks within the volume from 200ml-2000ml.different models can satisfy various requirement of output from 1000B/H to 22000B/H.Bottle washing filling,covering are realized by one machine.The whole machine is designed scientifically and reasonably,the appearance is good looking,the maintenance and repair is rather convenient,the hang type bottle opening clipping transport bottle structure makes it more convenient,rapid and labor saving to change type of bottles.The main machine has applied advanced inverter control technique,the key electric parts are all products of world famous brands.

This machine can reduce the temperature of hot filling drinks to 36 -40 ℃,or increase the temperature of cold filling carbonic acid drinks to 36-40℃. It is used in carbonated drinks,,hot tea drinks,juice drinks and production line. This machine can eliminate the condensed water on the external side of bottles ,keep bottle clean and dry. This makes bottles easier for labeling and package.

Using high pressure air ventilation, so that high-speed air flow ejected from a slit, the remaining drops of water bottles as much as possible the body blow it away. Inclination of the slit so that the entire side of the bottle can be high-speed air-blown.

The bottle dryer consists of the high pressure air fan, pressure tank, inflatable tube, rack, control devices, and other components.

Laser marking machines handle nearly every industrial marking and DPM (Direct Part Marking) task. Metals, plastics, ceramics, glass etc. are processed efficiently and contact-free. All desired contents are applied repeatedly accurate and reliably: 2D, DMC and alphanumeric codes, simple serial numbers, complex logos, graphics, structures. Depending on the material and application task, the process is laser marking, engraving or deep engraving.

This machine adopts international advanced technology; cover the circle label on the pet bottle. And then hot shrinking to fix on the position which bottle body designated. This machine's structure is compact, and suitable for the production line of different direction and different height.

The machinery part adopts combination designing of modularization, and makes the machine reasonable. The height adjustment adopts motor fluctuating; it is convenient to replace the material. The special cutter head designing, make the film-rolling cut more exactly and reliably.

The machine is suitable for wrapping of such products as pop top, mineral water , bottles. beer, drinks etc. Working with PE film shrink tunnel to pack the goods perfectly , the whole production process adopts the Germany advanced technics, and the main parts are imported from international famous companies. It consists of seven actuating motor, through cooperation with 7 actuating motor to form the product packed with plastic film and several bottles as a group out from the hot shrinking packing machine.

| Model | DCGF8-8-3 | DCGF14-12-5 | DCGF16-16-5 | DCGF24-24-6 | DCGF32-32-8 | DCGF40-40-10 |

| Capacity(500ML) | 1000BPH | 1000BPH | 1000BPH | 6000BPH | 9000BPH | 12000BPH |

| Washing Heads | 8 | 14 | 16 | 24 | 32 | 40 |

| Filling Heads | 8 | 12 | 16 | 24 | 32 | 40 |

| Capping Heads | 3 | 5 | 5 | 6 | 8 | 10 |

| Suitable Bottle | PET Bottle ,Plastic Bottle | |||||

| Diameter of bottle | Diameter: 55-110 MM | |||||

| Height Of Bottle | 150-310MM | |||||

| Suitable Cap | Plastic Screw Cap | |||||

| Weight | 1500kg | 2000kg | 3000kg | 5000kg | 7000kg | 7800kg |

| Main Motor Power | 1.2kw | 1.5kw | 3kw | 3kw | 3kw | 5.5kw |

1.Easy to operate and highly automated

2.Apply world famous brand products

3.Designed for bottling in a hygienic environment.

4.Using free-standing transfer star wheels