Welcome to our website

Water treatment system,also called water filtration sterlizer system, is the process of purifying the raw water by a series equipments and devices to be drinkable.The water treatment equipment includes silica sand filter, active carbon filter, sodium-ion exchanger, precision filter, reverse osmosis, hollow fiber filter, ozone generator, ozone mixing tower and water tank, etc.

The system include: sugar melting, syrup filter, syrup storage tank, diatomaceous filter, Mixing tank, hot water storage tank, homogenizer, vacuum de-aerator machine (degassing system) ,ultra-high temperature sterilizer and CIP.

Stainless steel mixing tanks are widely applied in the beverage, food, dairy, pharmaceutical, daily chemical and Cosmetic process industries used as blender tank, buffer tank and storage tank, which cleanable to sanitary standards .

UHT Plate type Sterilizer is PLC controlled,with optional capacity from 1t/hr to 15t/hr.The system work in aseptic section and normal section, for the technical require-ments of filling at low temperature,normal temperature and high temperature.

CIP is specially designed for the clean-up of beverage production line and filling equipment, with three cleaning sections of acid, alkali and heated water.

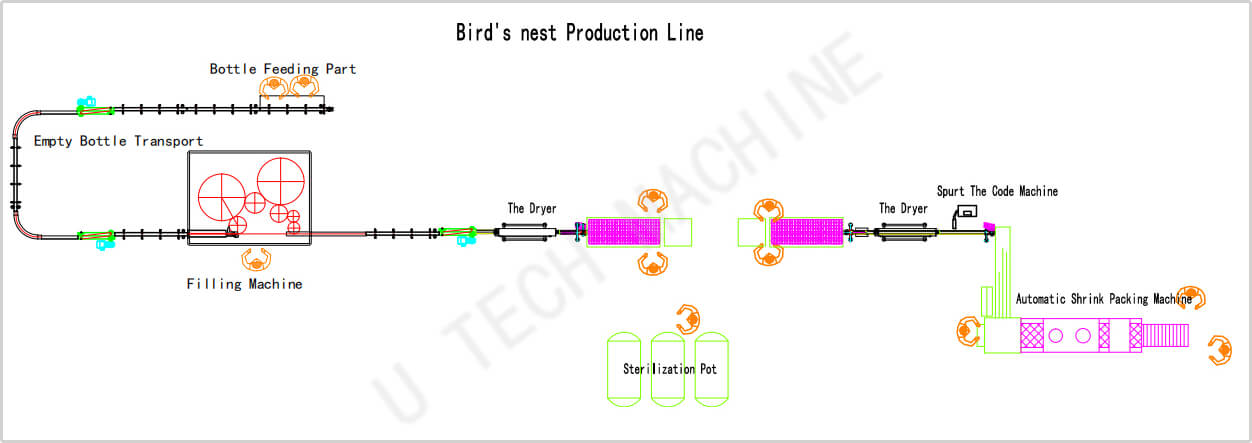

Bird nest filling machine is kind of piston filling machine. It is used to fill bird nest, ketchup, edible oil, mayonnaise into plastic bottles, glass bottles, aluminum can etc. Also it can fill water and juice.

All the processing is customize basing on the different production capacity per hour, filling liquid, bottle types and caps. Different liquid, bottle and cap are different, the filling valve, filling nozzle, bottle carry system are totally different.

Conveying path support on the ground by tripod, driving motor adopt frequency control, it connects with rinser filling and capping 3 in 1 machine and keeps pace with it. the filled bottles are conveyed by the conveyor system. Driving system is running by a main motor that adopts gear drive mode.

This sterilizing pot is a high pressure sterilizing pot, the can is placed in a sealed pressure container, with a certain pressure of saturated steam as the heating medium, so that the can can be sterilized in the static state of the equipment.It is characterized by simple structure and easy operation and maintenance.This sterilizing pot is sprayed with cold water after sterilization.The sterilization box in and out by manual operation.Sterilization time can be set arbitrarily according to the process requirements.The sterilization temperature is 121℃.

The glass bottle are sent to the canning platform by the conveyor belt, and the glass bottle are packed manually with a scraper. After the glassbottle are filled with one layer, they are separated by a partition. At the same time, the hydraulic cylinder is controlled to descend one compartment and another layer is filled until the sterilizing frame is filled.Finally, the sterilization box is pushed to the sterilization pot by hand for sterilization.This system is composed of a hydraulic lifting cylinder, hydraulic system, a canning platform and control system.Then through the electric trolley circulating track conveying system to the sterilization pot for sterilization, the whole process of cage fast, convenient, replace the way of man cage, save manpower, greatly improve the production efficiency.

Using high pressure air ventilation, so that high-speed air flow ejected from a slit, the remaining drops of water bottles as much as possible the body blow it away. Inclination of the slit so that the entire side of the bottle can be high-speed air-blown.

The bottle dryer consists of the high pressure air fan, pressure tank, inflatable tube, rack, control devices, and other components.

Main ink route adopts stable and reliable imported gear pump. Recycle ink route adopts imported diaphragm pump. It improve product stability and reliability.

Adhesive Labeling Machine is controlled by the PLC, HMI and servo drive labeling. The machine is easy to operate and has helping function and fault indication function. It is suitable for the self-adhesive labeling of round bottles.

Shrink wrappers are mainly used in beer, beverage, food, non-food industry such as glass and plastic bottle and box industry packing. Design aims at different model. Single lane shrink wrapper can pack 10-45cartons per minute.

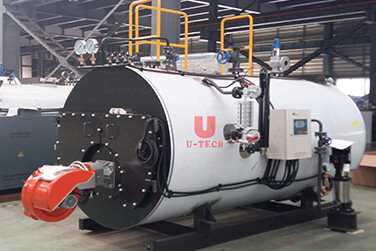

These industrial steam boilers are designed to efficiently meet the demands of instantaneous steam. For achieving perfect combustion, it includes precisely designed smoke passages & combustion chambers.

| Model | UTYW-14-12-5 |

| Washing Heads | 14 |

| Filling Heads | 12 |

| Capping Heads | 5 |

| Capacity | 5000BPH |

| Main Power | 4KW |

| Dimensions | 2700*2500*2400mm |

| Weight | 3500KG |

1.Easy to operate and highly automated

2.Apply world famous brand products

3.Designed for bottling in a hygienic environment.

4.Using free-standing transfer star wheels