Welcome to our website

The pet stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine. It has various cavities and the maximum capacity of the products is 20L. It can blow bottles in shapes: Carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers etc. Which is made of plastic of crystalline type, such as PET and PP etc.

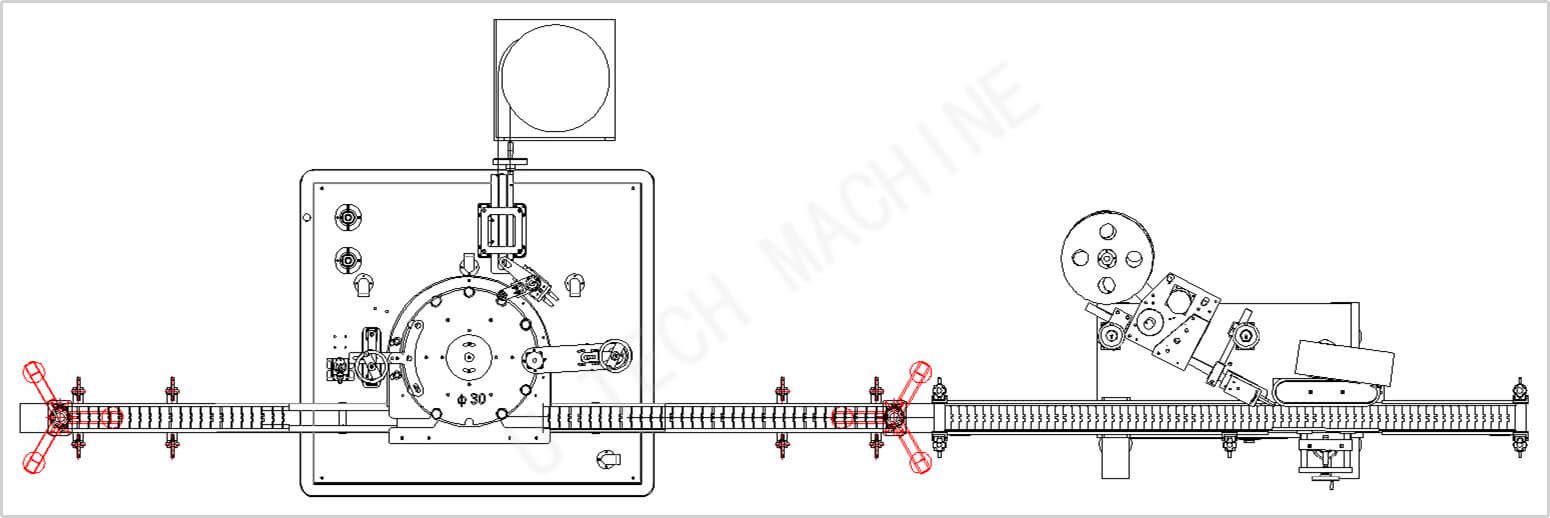

UT series Automatic rotary type PET bottle oil filling machine / small oil bottling machine is capable for bottle volumes from 250ml to 2000ml. It is with liquid crystal display, precise quantitative filling volume, and no leakage. There is overload clutch protection device at the star wheels of bottle in-feed and out-feed, so the machine will automatically stop and alarm if abnormal case happens.

Laser marking machines handle nearly every industrial marking and DPM (Direct Part Marking) task. Metals, plastics, ceramics, glass etc. are processed efficiently and contact-free. All desired contents are applied repeatedly accurate and reliably: 2D, DMC and alphanumeric codes, simple serial numbers, complex logos, graphics, structures. Depending on the material and application task, the process is laser marking, engraving or deep engraving.

This machine adopts international advanced technology; cover the circle label on the pet bottle. And then hot shrinking to fix on the position which bottle body designated. This machine's structure is compact, and suitable for the production line of different direction and different height.

The machinery part adopts combination designing of modularization, and makes the machine reasonable. The height adjustment adopts motor fluctuating; it is convenient to replace the material. The special cutter head designing, make the film-rolling cut more exactly and reliably.

Fully automatic case erector is working on unformed carton boxes that will automatic forming,folding and sealing for carton boxes.then it will be sealing by adhesive tape at carton boxes bottom.the machine has adopted Siemens touch and Siemens PLC as control system so that the operator easy to operation it and modify program in future.the case erector not only can independent work but also can combined with packing line together.

In the whole package line,case packer is the whole system.Case packer will transport and pack the finished product in to paper box according to the required arrange.Case packer manufactured by our company is sway model full auto case packer.

Can automatically fold the top cover and seal the upper and lower of carton. The auxiliary wheels on both sides assist the machine to seal the box, which ensures that the adhesive tape will not be skewed. Immediately after the L-shaped corner push, the carton is conveyed to perform the four-corner sealing operation, which is simple and practical. This type of sealing machine is widely used in food, medicine, beverage, tobacco, daily chemical and other domestic and foreign industries.

| Model | Filling heads and capping heads | Production capacity (bottles per hour for 500ml) | Main motor power(kw) |

| UT12/5 | 12, 5 | 2000-3000 BPH | 3.58 |

| UT16/5 | 16, 5 | 4000-5000 BPH | 3.58 |

| UT18/6 | 18, 6 | 6000-7000 BPH | 4.68 |

| UT24/8 | 24, 8 | 9000-10000 BPH | 4.68 |

| UT32/10 | 32, 10 | 12000-14000 BPH | 6.58 |

| UT40/12 | 40, 12 | 15000-18000 BPH | 6.58 |

1.Easy to operate and highly automated

2.Apply world famous brand products

3.Designed for bottling in a hygienic environment.

4.Using free-standing transfer star wheels