Welcome to our website

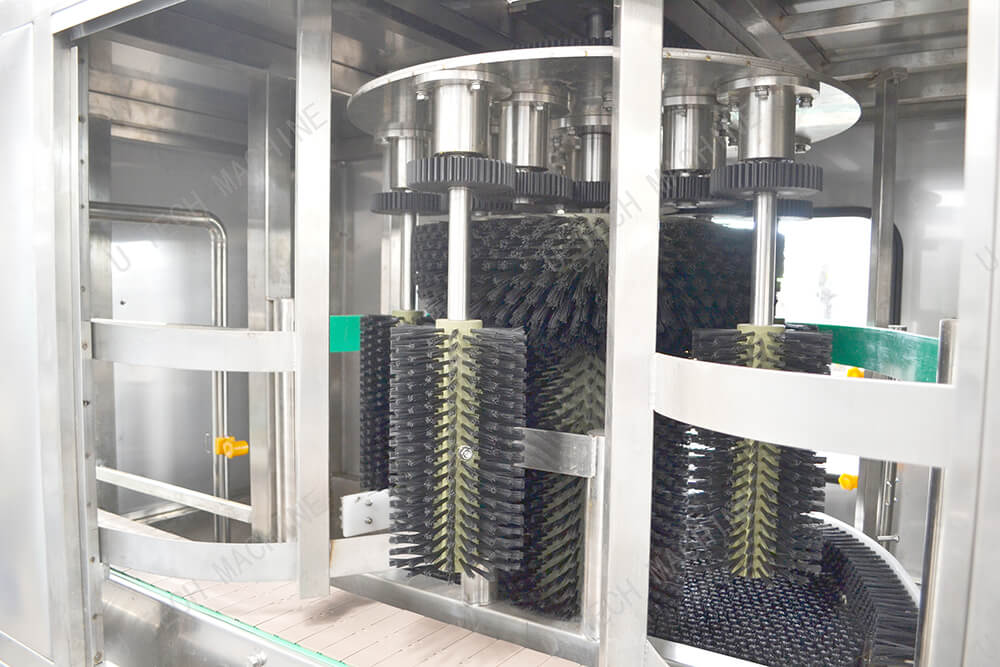

This QGF series barreled water fiiling line is mainly used to produce bottled water with volume from 3 gallon to 5 gallon.And different models can offer production capacity from 100 to 2000B/H.The whole production process operates as follows:Empty barrel are conveyed into decapping machine,which will remove bottle caps.Those caps can be recycled after being cleaned and disinfected.Then barrel are conveyed into the extemal bursh washing machine to take all-round ringsing with hot alkali and pure water.After ringsed,barrel will be sent to ringsing filling capping machine,where bottles are ringsed inside with hot alkali,disinfectant liquid and pure water.and then barrel is filled with pure water provided by water treatment system.Then after capped,those barreled water is sent to shrink packing machine in which shrink packaging of caps is done.

| Model | QGF-100 | QGF-150 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 | QGF-1500 | QGF-2000 |

Capacity (5 gallon) | 100BPH | 150BPH | 300BPH |

450BPH | 600BPH | 900BPH | 1200BPH |

1500BPH | 2000BPH |

| Working position number | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 17 | 21 |

| Filling heads | 1 | 1 | 2 | 3 | 4 | 8 | 10 | 12 | 15 |

| Capping heads | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Suitable bottle | PET bottle,plastic bottle | ||||||||

| Diameter of bottle | φ265-273mm | ||||||||

| Height of bottle | 150-360mm | ||||||||

| Suitable cap | Plastic cap | ||||||||

| Weight | 450kg | 500kg | 2500kg | 3000kg | 3500kg | 7000kg | 8000kg | 8500kg | 9500kg |

| Main motor power | 1.41kw | 1.5kw | 6kw | 30kw | 32kw | 35kw | 40kw | 45kw | 52kw |