Welcome to our website

Individuals that are just starting their packaging business with a new product or have an established product can no longer make use of hand during the filling process because of the excessive high demand; however there are several kinds of filling machines which are offered by manufacturer so as to ease the filling task. For example, the two which are very popular when it comes to filling bottles are overflow and gravity fillers. Yet there are several people that know little about these filling machine but we would discuss about them and also show why overflow filling machine is the clear choice.

Overflow filling

During the manufacturing of bottles, an attempt is always made to keep the process as consistent as possible for some reasons. Most packagers would want each and every container to be very similar so as to enhance shelf appeal and small inconsistencies may be identifiable by merely looking at them. However, when liquids are added to the bottles with slight variation in the volume, the visible fill level would vary but the container has the same quantity of product. The overflow filling machine can be used to combat these inconsistencies in volume by filling each and every bottle to the exact level regardless of the volume contained in them.

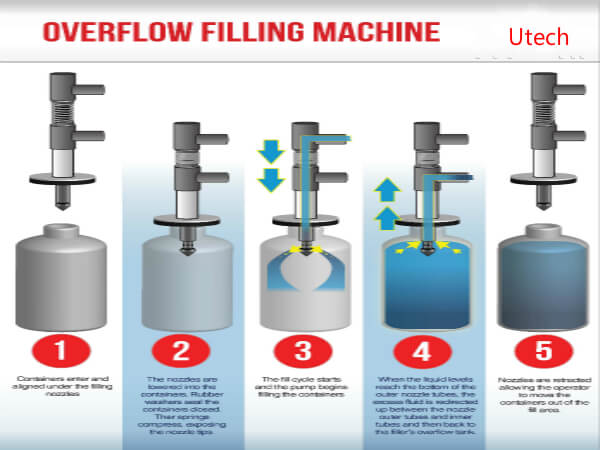

The overflow fillers usually achieve this level fill by making use of a unique nozzle which would seat over the opening of the bottle and also allows the product to flow back via the nozzle to the holding tank or reservoir, thereby preventing the wastage of product. As the nozzle seals over the bottle, the fill port would be opened so that the product can enter the bottle. After the product has gotten to a specific point in the container, controlled by using spacers on each of the fill heads, the product exits the bottle through the return port, overflowing out of the bottle and back into the reservoir. This principle can be replicated for free flowing products in containers both large and small but great variations in price may require various sizes of nozzle so as to enhance efficiency.

As earlier stated, the level of fill can mean that the actual volume of product will vary from one container to another. While this can be a major concern to big industries such as distilled spirits, pharmaceuticals as well as other volume requirements, nearly all the industries have their target volume as well as an acceptable range. In most cases, the change in the interior volume will be minimal that the danger of falling outside of acceptable range won’t exist. However, packagers that have this concern will want to ensure their bottle manufacturer provide a bottle with uniform bottle size. This also serves as a quality control measure so as to ensure the production process goes on smoothly.

Overflow filling machine likewise serves as an ideal solution for glass as well as other clear containers, for instance a typical 750ml distilled spirits bottle or clear plastic beverages bottles. By filling these kinds of bottle to a particular level, you would be ensured of a perfect, even as well as consistent filling.